Ennar Spinning Mills

Overview

Ennar Spinning Mills, a long-standing yarn manufacturer in Coimbatore founded in 1992, installed a 700 kW AC / 875 kW DC solar power system using SolarEdge inverters with optimizers to cut power costs and lower environmental impact.

Execution

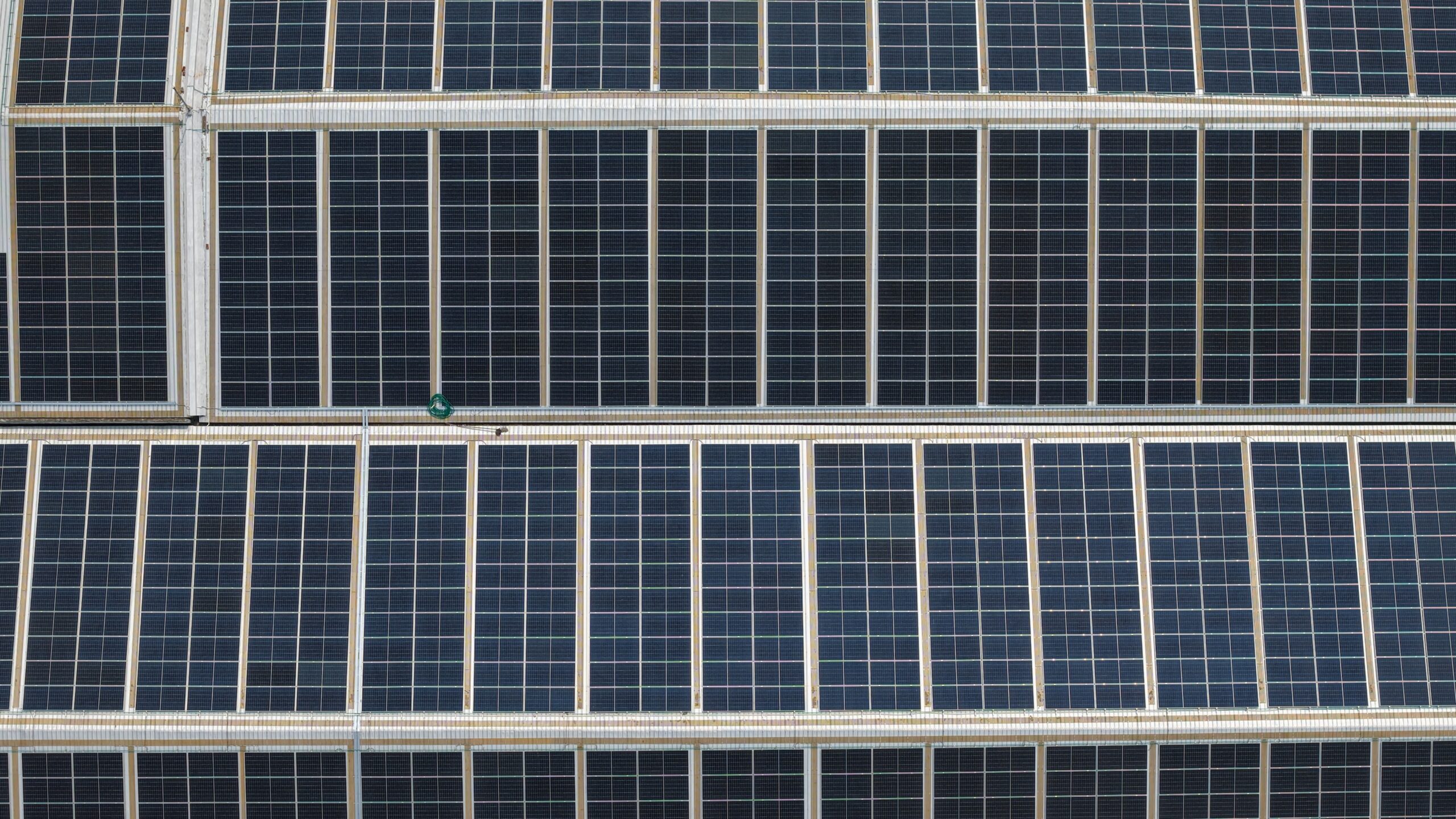

Ennar Spinning Mills operates from its large facility in Kunnathur Pudur, producing various types of cotton yarn. To meet high daytime energy demand (for spinning, motoring, lighting, etc.), they installed high-wattage Goldi 550 Wp panels paired with SolarEdge inverters and module-level optimizers. The setup spans factory rooftops with good solar exposure. A monitoring system is part of the installation, enabling visibility into power generation and helping ensure optimum performance.

Result

Electricity Bill Reduction: The solar system is estimated to cover about 20-25% of the mill’s daytime load, resulting in significant monthly savings in energy costs.

CO₂ Emissions Prevented: The clean energy produced avoids approximately 1,200-1,400 tonnes of CO₂ emissions annually, assuming typical regional solar yields and grid emission factors.

Smart Monitoring: With module-level monitoring (through optimizers) and centralized dashboards, Ennar can track each string’s performance, detect shading or issues, and maintain efficiency.

Property & Brand Value: This investment enhances the value of the property (lower running costs, less grid dependency) and strengthens Ennar’s reputation as a sustainable, energy-wise company in the textile sector.